Hot Melt Adhesive for Express Bags Industry

Hot melt adhesives formulated for the express bags (courier bags) industry are engineered to deliver instant bonding, robust security, and excellent processability on low-surface-energy substrates such as LDPE, LLDPE, or co-extruded films. These adhesives are typically delivered as hot-applied extrudates or coated molten formulations onto sealing strips integrated into the bag structure. Key functional demands include high initial hot-tack for immediate closure, irreversible bond strength to deter tampering, stable viscosity across operating temperatures for consistent application, and compatibility with high-speed converting lines.

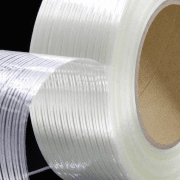

Structurally, the product is a carefully balanced blend of thermoplastic polymers (commonly EVA, metallocene polyolefins, or tailored polyolefin copolymers), tackifiers, waxes, and additives that jointly control melt viscosity, open time, and final adhesive performance. Formulation adjustments enable fine-tuning: higher tackifier loads boost initial adhesion; specific polymer choices enhance peel strength and temperature resistance; and antioxidants or stabilizers improve shelf-life and thermal stability during processing.

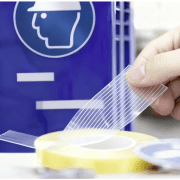

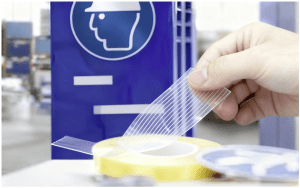

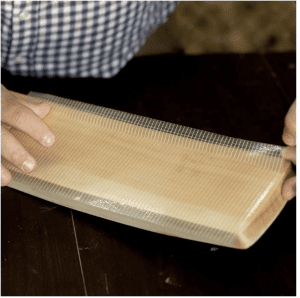

Performance characteristics include rapid setting upon closure, strong peel values on low-energy films, resistant bonds across a broad temperature window (typically -20°C to +80°C service), and durable adhesion under mechanical stress and rough handling. For express bag applications, the adhesive must also show good aging properties—retaining bond integrity after

storage and transport—and strong tamper-evident behavior: attempts to reopen the bag should either delaminate the substrate or produce clear visual evidence of interference.

storage and transport—and strong tamper-evident behavior: attempts to reopen the bag should either delaminate the substrate or produce clear visual evidence of interference.

Operational demands in converting require adhesives with narrow and repeatable melt viscosity profiles, low stringing during application, and stable behavior at high line speeds (often hundreds of meters per minute). Adhesives must also be compatible with lamination and slitting operations, and some formulations are optimized for solventless hot-coating processes to meet environmental and VOC concerns.

Applications cover courier bag sealing strips, tamper-evident security envelopes, adhesive closures on poly mailers, and permanently sealed luggage tags. They are critical to e-commerce logistics, secure document transport, and any application where parcel integrity is mission-critical. The adhesive enables manufacturers to produce user-activated, reliable seals that consumers can apply quickly while preserving parcel confidentiality and transit resilience.

Market dynamics are strongly tied to e-commerce volume growth, logistics automation, and security regulations. As global parcel shipments continue to surge, demand for dependable, high-performance sealing adhesives grows commensurately. Innovations focus on lowering processing temperatures for energy savings, enhancing adhesive performance on recyclable film substrates, and developing formulations compatible with bio-based polymers.

Sustainability pressures are prompting suppliers to explore recyclable adhesive syst ems that allow the bag substrate to be reclaimed without contamination, and to reduce VOCs and processing energy. In summary, hot melt adhesives for express bags are a technically demanding, high-volume segment critical to modern logistics—balancing processability, security, and environmental considerations.

ems that allow the bag substrate to be reclaimed without contamination, and to reduce VOCs and processing energy. In summary, hot melt adhesives for express bags are a technically demanding, high-volume segment critical to modern logistics—balancing processability, security, and environmental considerations.