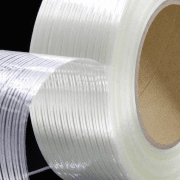

Double Sided Tissue Tape: A Reliable Choice for Zipper Carton Sealing Applications

As the demand for high-quality packaging solutions continues to grow, Weasy’s cotton paper double-sided tape stands out as a leading choice for sealing high-end zipper cartons. This innovative tape combines strength, versatility, and eco-friendliness, making it an ideal solution for various bonding applications in the packaging industry.

The foundation of Weasy’s Double Sided Tissue Tape is its high-strength cotton paper, which provides exceptional durability and flexibility. The tape is coated on both sides with a specially formulated high-tack adhesive that is residue-free and environmentally friendly. This ensures that the tape not only performs well but also aligns with sustainability goals, making it a responsible choice for manufacturers.

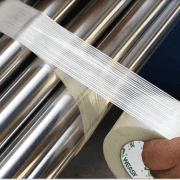

One of the notable advantages of Weasy’s tape is its superior performance in low-temperature conditions. This feature is especially beneficial for applications where temperature fluctuations can impact adhesive effectiveness. The tape retains its strong bonding capabilities, ensuring that zipper cartons remain securely closed during shipping and handling, regardless of external conditions.

Moreover, Weasy’s Double Sided Tissue Tape is designed to be waterproof and moisture-resistant, providing an extra layer of protection for packaged goods. This is particularly important in postal and packaging industries, where products may be exposed to varying levels of humidity and moisture. The tape’s anti-rebound properties ensure that it adheres firmly to surfaces, preventing any unintended openings that could lead to product damage.

In practical terms, Weasy’s Double Sided Tissue Tape is ideal for sealing zipper cartons used in various sectors, including e-commerce, retail, and logistics. Its reliable performance and ease of use make it a preferred choice for manufacturers looking to enhance their packaging solutions.

In conclusion, Weasy’s Double Sided Tissue Tape offers a robust and effective solution for sealing high-end zipper cartons. Its combination of strength, low-temperature performance, and moisture resistance makes it a valuable asset for businesses in the packaging industry. By choosing Weasy, companies can enhance their packaging efficiency while ensuring product integrity and customer satisfaction..

ems that allow the bag substrate to be reclaimed without contamination, and to reduce VOCs and processing energy. In summary, hot melt adhesives for express bags are a technically demanding, high-volume segment critical to modern logistics—balancing processability, security, and environmental considerations.

ems that allow the bag substrate to be reclaimed without contamination, and to reduce VOCs and processing energy. In summary, hot melt adhesives for express bags are a technically demanding, high-volume segment critical to modern logistics—balancing processability, security, and environmental considerations.