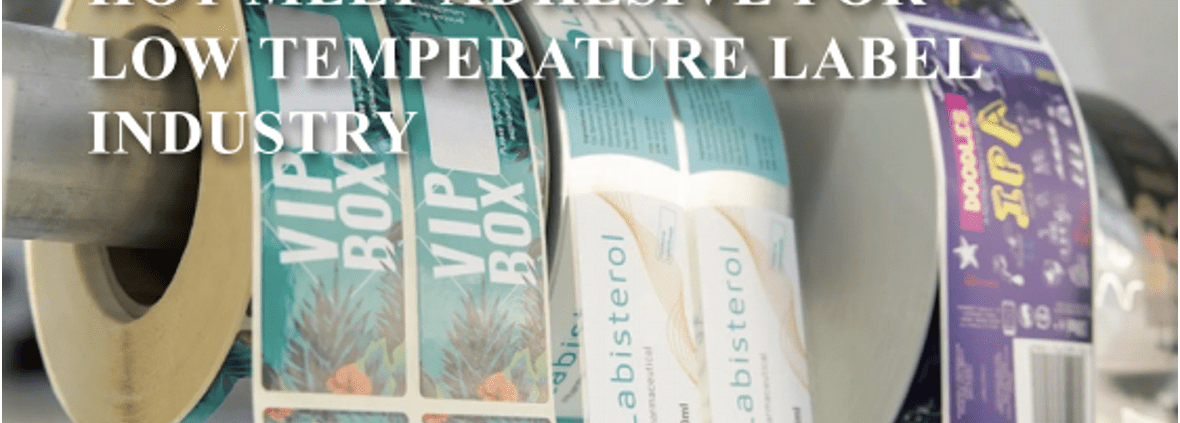

Hot Melt Adhesive for Low Temperature Label Industry

Hot melt adhesives tailored for the low-temperature label industry are highly engineered polymer systems designed to deliver rapid, reliable adhesion in sub-zero environments while maintaining excellent performance across the supply chain—from cold storage to retail shelf. These adhesives are formulated to adhere instantly to chilled, frosted, or even lightly wet surfaces found in refrigerated and frozen product packaging, and they retain peel and shear strength even at temperatures as low as -20°C to -40°C depending on the grade.

At the formulation level, low-temperature hot melts typically combine flexible polymer backbones (such as EVA-based or specially modified polyolefins), low-temperature tackifiers, plasticizers, and stabilizers. The plasticizer and resin selection ensures the adhesive remains soft and tacky at low temperatures—preventing the common failure mode of embrittlement. Careful balance yields adhesives that can wet the substrate at application temperature, develop initial tack rapidly to support high-speed labeling, and then provide durable bond strength during cold-chain transit.

Critical performance features include immediate adhesion on chilled surfaces, strong low-temperature peel values, resistance to moisture and condensation (common in defrost cycles), and minimal edge lift or label curl. Because many labeling operations occur at high line speeds, the adhesive must also have controlled open time and set profile to ensure placement accuracy. Additionally, compatibility with common label facestocks (paper, BOPP, PET) and container substrates (HDPE, PET, glass, metal) is essential.

Typical application sectors are frozen foods, dairy and chilled beverages, pharmaceutical cold-chain packaging, and industrial chemicals stored at low temperatures. The adhesives are used in pressure-sensitive labels, in-mold labels, and some shrink sleeve pre-adhesive systems for refrigerated SKU identification. In the pharmaceutical sector, label adhesion reliability is crucial for track-and-trace, compliance, and patient safety, particularly where labels must not peel in cold transport or storage.

Market demand for low-temperature labeling adhesives has grown substantially with the expansion of global cold-chain logistics. As consumer demand for frozen foods, refrigerated meal kits, and temperature-controlled pharmaceuticals increases, the need for adhesives that perform reliably in these environments escalates. Regulatory and traceability requirements further intensify demand, since labels must stay affixed and legible throughout the product lifecycle.

Innovation trends center on bio-based and recyclable adhesive chemistries compatible with circular packaging systems, reduced migration formulations for food and pharma safety, and enhanced adhesion on recyclable polyethylene containers. Suppliers are also developing adhesives optimized for lower application temperatures to save energy at labeling lines. In summary, hot melt adhesives for low-temperature labels are a mission-critical component of modern cold-chain logistics—ensuring identification, compliance, and product integrity from freezer to fork.

Discover the Benefits of Weasy Residue-Free Fiberglass Tape in Home Appliances

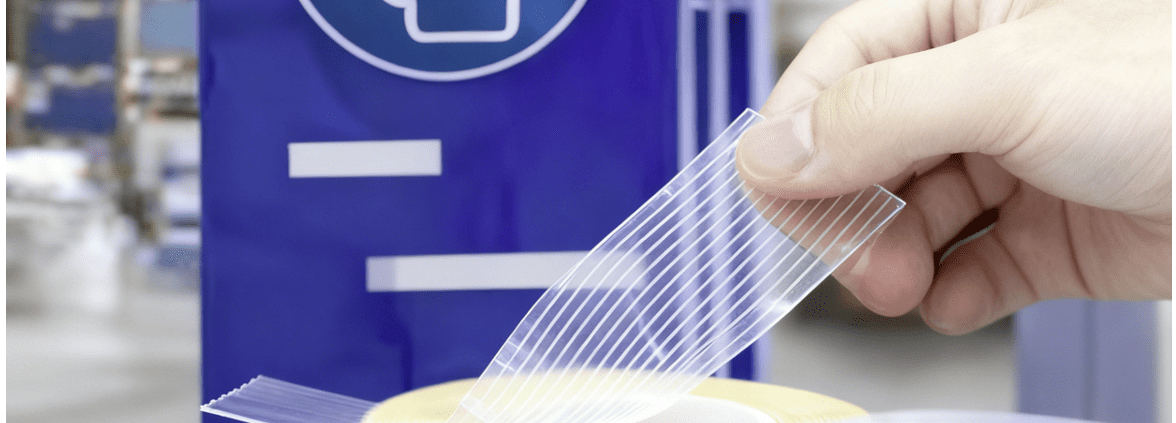

The home appliance industry faces numerous challenges, particularly when it comes to securing components during production and transport. One of the most common issues manufacturers encounter is the use of traditional adhesive tapes that leave behind unsightly residues, detracting from the product’s overall appearance. Weasy’s residue-free fiberglass tape is designed to solve this problem effectively, providing a seamless and reliable solution for temporary fixation.

Picture a refrigerator assembly line where multiple parts need to be held in place before final assembly. The use of Weasy’s fiberglass tape allows manufacturers to secure plastic trays and shelves without worrying about adhesive marks that could compromise the appliance’s finish. This tape is engineered with a high-strength fiberglass fabric and a unique pressure-sensitive adhesive that ensures a strong bond while allowing for easy removal. This feature is particularly beneficial for manufacturers who need to make adjustments or conduct quality checks during the assembly process.

Moreover, Weasy’s tape is versatile enough to handle various materials, from metal to plastic, making it suitable for a wide range of appliances. Its high tensile strength ensures that it can withstand the stresses of transportation, keeping components securely in place even during rough handling. This durability reduces the risk of damage and enhances the overall reliability of the product, addressing a critical concern for manufacturers.

In addition to its functional benefits, Weasy’s residue-free fiberglass tape promotes a cleaner and more professional appearance for home appliances. By eliminating the risk of residue, manufacturers can deliver products that not only perform well but also look impeccable. This attention to detail can significantly enhance customer satisfaction and brand reputation in a competitive market.

In conclusion, Weasy’s residue-free fiberglass tape is an invaluable asset for the home appliance industry. By addressing the common pain points of securing components and maintaining product aesthetics, Weasy provides manufacturers with a reliable solution that enhances both operational efficiency and customer satisfaction. Choosing Weasy means investing in quality and excellence for your home appliances.

Application of Hot Melt Adhesives in Eyeglass Case Manufacturing

Hot melt adhesives have become an essential bonding material in the production of eyeglass cases due to their versatility, durability, and efficiency. These adhesives provide strong adhesion to a wide range of substrates, offer clean and efficient processing, and ensure long-term stability of the finished products. Depending on the type of eyeglass case—metal, plastic, leather, nylon, or wood—hot melt adhesives play a specific role in ensuring both functionality and aesthetics

For metal eyeglass cases, hot melt adhesives are mainly used to bond the inner lining materials, such as fabric or velvet, to the rigid metal shell. This creates a soft protective interior that prevents scratches on lenses while maintaining a firm structure. The quick-setting property of hot melts is particularly advantageous in mass production, where speed and precision are critical.

In plastic cases, hot melt adhesives are applied to secure inner layers, coverings, or decorative films. Plastics often require adhesives that can bond well despite smooth and sometimes low-energy surfaces. Formulated hot melts ensure reliable adhesion, preventing peeling or detachment during use. Additionally, the flexibility of the adhesive allows the case to open and close repeatedly without weakening the bond.

For leather eyeglass cases, hot melt adhesives serve both structural and aesthetic functions. They are used to attach leather or synthetic PU leather coverings to the inner stiffeners, often made of cardboard or plastic. Hot melts create a smooth, wrinkle-free surface while providing the strength needed for everyday handling. Their clean bonding ensures that no residue seeps through the leather surface, which is essential for premium-quality products.

Nylon and EVA-based eyeglass cases, often used for sports and outdoor eyewear, rely on hot melt adhesives for bonding outer nylon fabrics to molded EVA or plastic shells. These adhesives provide durability, flexibility, and resistance to temperature variations, ensuring the case maintains its protective qualities under different environmental conditions. The heat resistance of hot melts also ensures that the adhesive does not degrade during storage or outdoor use.

For wooden eyeglass cases, hot melt adhesives are typically employed to attach lining fabrics and cushioning materials inside the rigid wooden frame. Since wood is porous, hot melts penetrate slightly into the surface, forming a secure and lasting bond. This combination of natural wood aesthetics with reliable adhesive bonding produces cases that are both elegant and durable.

In conclusion, hot melt adhesives are indispensable in modern eyeglass case manufacturing. Their adaptability across different materials—metal, plastic, leather, nylon, and wood—ensures that manufacturers can achieve both structural integrity and visual appeal. By providing strong adhesion, fast processing, and long-term reliability, hot melt adhesives have become a cornerstone of efficient and high-quality eyeglass case production.