Double Sided Tissue Tape: A Reliable Choice for Zipper Carton Sealing Applications

As the demand for high-quality packaging solutions continues to grow, Weasy’s cotton paper double-sided tape stands out as a leading choice for sealing high-end zipper cartons. This innovative tape combines strength, versatility, and eco-friendliness, making it an ideal solution for various bonding applications in the packaging industry.

The foundation of Weasy’s Double Sided Tissue Tape is its high-strength cotton paper, which provides exceptional durability and flexibility. The tape is coated on both sides with a specially formulated high-tack adhesive that is residue-free and environmentally friendly. This ensures that the tape not only performs well but also aligns with sustainability goals, making it a responsible choice for manufacturers.

One of the notable advantages of Weasy’s tape is its superior performance in low-temperature conditions. This feature is especially beneficial for applications where temperature fluctuations can impact adhesive effectiveness. The tape retains its strong bonding capabilities, ensuring that zipper cartons remain securely closed during shipping and handling, regardless of external conditions.

Moreover, Weasy’s Double Sided Tissue Tape is designed to be waterproof and moisture-resistant, providing an extra layer of protection for packaged goods. This is particularly important in postal and packaging industries, where products may be exposed to varying levels of humidity and moisture. The tape’s anti-rebound properties ensure that it adheres firmly to surfaces, preventing any unintended openings that could lead to product damage.

In practical terms, Weasy’s Double Sided Tissue Tape is ideal for sealing zipper cartons used in various sectors, including e-commerce, retail, and logistics. Its reliable performance and ease of use make it a preferred choice for manufacturers looking to enhance their packaging solutions.

In conclusion, Weasy’s Double Sided Tissue Tape offers a robust and effective solution for sealing high-end zipper cartons. Its combination of strength, low-temperature performance, and moisture resistance makes it a valuable asset for businesses in the packaging industry. By choosing Weasy, companies can enhance their packaging efficiency while ensuring product integrity and customer satisfaction..

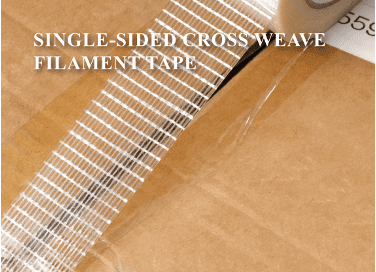

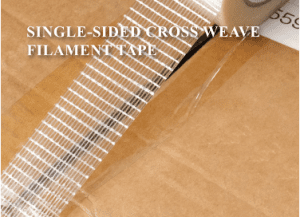

Single-Sided Cross Weave Filament Tape

Single-sided cross weave filament tape is a heavy-duty industrial adhesive tape reinforced with fiberglass filaments woven in both the longitudinal and transverse directions. This cross-weave structure significantly enhances the tape’s tear resistance and tensile strength, giving it a balanced strength profile ideal for demanding packaging and reinforcement applications. The filaments are anchored onto a tough PET film backing, which is then coated with a high-performance pressure-sensitive adhesive.

The cross-weave reinforcement provides superior durability compared with unidirectional filament tapes. The bidirectional fiber arrangement allows the tape to resist deformation, splitting, and tearing—even under multi directional stresses. This makes it ideal for securing irregular loads, reinforcing weak packaging materials, and stabilizing components during transport. Additionally, the woven design enhances abrasion resistance, enabling the tape to withstand rough handling common in shipping, construction, and manufacturing environments.

The adhesive layer ensures strong bonding to cardboard, plastic, metal, wood, and textile surfaces. It provides consistent adhesion even on slightly uneven or dusty substrates, which is advantageous in industrial settings. The tape also offers good resistance to temperature fluctuations and moisture, maintaining reliability during long storage periods or cross-border transport.

Cross weave filament tape is widely used for pallet unitization, heavy carton reinforcement, bundling of construction materials, securing metal parts, and general-purpose industrial reinforcement. It is commonly applied in export packaging, automotive parts logistics, hardware distribution, and large appliance transportation.

As global supply chains continue to expand, industries increasingly require packaging materials that can withstand long-distance transport and prevent in-transit damage. Single-sided cross weave filament tape meets these demands with superior strength and stability, making it a vital material in the modern logistics and manufacturing sectors.

Hot Melt Adhesive for Express Bags Industry

Hot melt adhesives formulated for the express bags (courier bags) industry are engineered to deliver instant bonding, robust security, and excellent processability on low-surface-energy substrates such as LDPE, LLDPE, or co-extruded films. These adhesives are typically delivered as hot-applied extrudates or coated molten formulations onto sealing strips integrated into the bag structure. Key functional demands include high initial hot-tack for immediate closure, irreversible bond strength to deter tampering, stable viscosity across operating temperatures for consistent application, and compatibility with high-speed converting lines.

Structurally, the product is a carefully balanced blend of thermoplastic polymers (commonly EVA, metallocene polyolefins, or tailored polyolefin copolymers), tackifiers, waxes, and additives that jointly control melt viscosity, open time, and final adhesive performance. Formulation adjustments enable fine-tuning: higher tackifier loads boost initial adhesion; specific polymer choices enhance peel strength and temperature resistance; and antioxidants or stabilizers improve shelf-life and thermal stability during processing.

Performance characteristics include rapid setting upon closure, strong peel values on low-energy films, resistant bonds across a broad temperature window (typically -20°C to +80°C service), and durable adhesion under mechanical stress and rough handling. For express bag applications, the adhesive must also show good aging properties—retaining bond integrity after

storage and transport—and strong tamper-evident behavior: attempts to reopen the bag should either delaminate the substrate or produce clear visual evidence of interference.

storage and transport—and strong tamper-evident behavior: attempts to reopen the bag should either delaminate the substrate or produce clear visual evidence of interference.

Operational demands in converting require adhesives with narrow and repeatable melt viscosity profiles, low stringing during application, and stable behavior at high line speeds (often hundreds of meters per minute). Adhesives must also be compatible with lamination and slitting operations, and some formulations are optimized for solventless hot-coating processes to meet environmental and VOC concerns.

Applications cover courier bag sealing strips, tamper-evident security envelopes, adhesive closures on poly mailers, and permanently sealed luggage tags. They are critical to e-commerce logistics, secure document transport, and any application where parcel integrity is mission-critical. The adhesive enables manufacturers to produce user-activated, reliable seals that consumers can apply quickly while preserving parcel confidentiality and transit resilience.

Market dynamics are strongly tied to e-commerce volume growth, logistics automation, and security regulations. As global parcel shipments continue to surge, demand for dependable, high-performance sealing adhesives grows commensurately. Innovations focus on lowering processing temperatures for energy savings, enhancing adhesive performance on recyclable film substrates, and developing formulations compatible with bio-based polymers.

Sustainability pressures are prompting suppliers to explore recyclable adhesive syst ems that allow the bag substrate to be reclaimed without contamination, and to reduce VOCs and processing energy. In summary, hot melt adhesives for express bags are a technically demanding, high-volume segment critical to modern logistics—balancing processability, security, and environmental considerations.

ems that allow the bag substrate to be reclaimed without contamination, and to reduce VOCs and processing energy. In summary, hot melt adhesives for express bags are a technically demanding, high-volume segment critical to modern logistics—balancing processability, security, and environmental considerations.