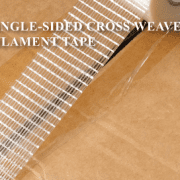

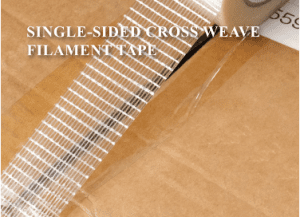

Single-Sided Cross Weave Filament Tape

Single-sided cross weave filament tape is a heavy-duty industrial adhesive tape reinforced with fiberglass filaments woven in both the longitudinal and transverse directions. This cross-weave structure significantly enhances the tape’s tear resistance and tensile strength, giving it a balanced strength profile ideal for demanding packaging and reinforcement applications. The filaments are anchored onto a tough PET film backing, which is then coated with a high-performance pressure-sensitive adhesive.

The cross-weave reinforcement provides superior durability compared with unidirectional filament tapes. The bidirectional fiber arrangement allows the tape to resist deformation, splitting, and tearing—even under multi directional stresses. This makes it ideal for securing irregular loads, reinforcing weak packaging materials, and stabilizing components during transport. Additionally, the woven design enhances abrasion resistance, enabling the tape to withstand rough handling common in shipping, construction, and manufacturing environments.

The adhesive layer ensures strong bonding to cardboard, plastic, metal, wood, and textile surfaces. It provides consistent adhesion even on slightly uneven or dusty substrates, which is advantageous in industrial settings. The tape also offers good resistance to temperature fluctuations and moisture, maintaining reliability during long storage periods or cross-border transport.

Cross weave filament tape is widely used for pallet unitization, heavy carton reinforcement, bundling of construction materials, securing metal parts, and general-purpose industrial reinforcement. It is commonly applied in export packaging, automotive parts logistics, hardware distribution, and large appliance transportation.

As global supply chains continue to expand, industries increasingly require packaging materials that can withstand long-distance transport and prevent in-transit damage. Single-sided cross weave filament tape meets these demands with superior strength and stability, making it a vital material in the modern logistics and manufacturing sectors.

ems that allow the bag substrate to be reclaimed without contamination, and to reduce VOCs and processing energy. In summary, hot melt adhesives for express bags are a technically demanding, high-volume segment critical to modern logistics—balancing processability, security, and environmental considerations.

ems that allow the bag substrate to be reclaimed without contamination, and to reduce VOCs and processing energy. In summary, hot melt adhesives for express bags are a technically demanding, high-volume segment critical to modern logistics—balancing processability, security, and environmental considerations.